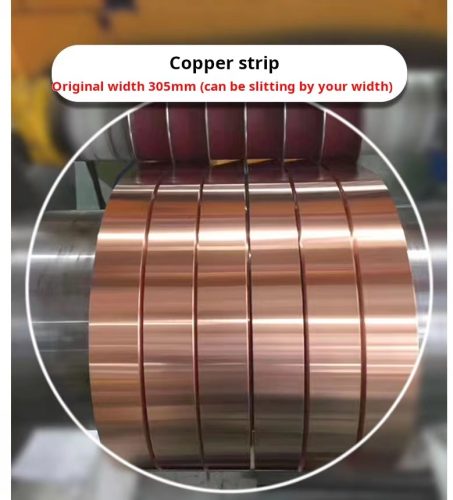

Stretching Copper Strip 1mm Hardware Processing Semi-hard T2 Pure Copper Foil Soft Connection Conductive C1100 Copper Coil

Description:

The copper materials of various specifications we provide are mainly used in new energy vehicles, screw factories, rivet factories, etc., as well as special cables and composite wires, computer cables, digital transmission cables, instrumentation cables, high temperature self-temperature controlling cables, electronic Instrument lead wires. After being enameled, they can be used in audio equipment, micromotors, instruments, aerospace, etc.

Technical Parameter

| Name | Copper Strip/Copper Foil /Copper Coil |

| Grade | C1100/T2 |

| Material | Red Copper |

| Specifications | 0.1~2mm |

| Copper Content | 99.90% |

| Minimum Order Quantity | 5kg in strips |

| Material Tolerance | Plus or minus 0.1mm |

| Environmental Requirement | Please consult customer service |

| Certificate | Material certification, SGS, CODELCO |

| Usage | Soft connection, Hardware processing, Wire and Cable, New Energy, Shielding Room |

| Feature | High Purity Conductivity |

| Save Environment | Keep the storage place clean and dry, avoid being stored in an environment with dust, ash, high temperature, and SO2. |

| Package | The packaging uses cloth + kraft paper + protective film (waterproof, scratch-resistant), for the large goods, we use the Pallet wooden box to prevent deformation. |

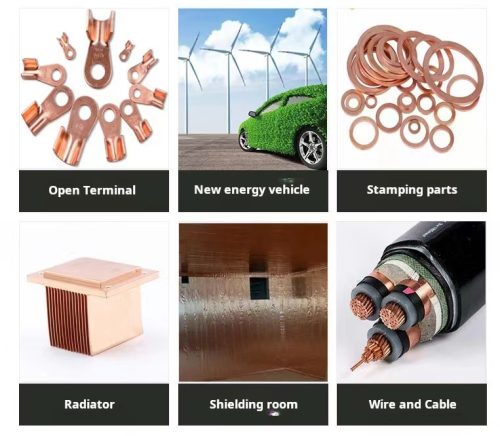

Application

Open end terminal, new energy vehicle, stamping parts, radiator, shielding room, wire and cable, etc.

Product Picture

Package

Workshop

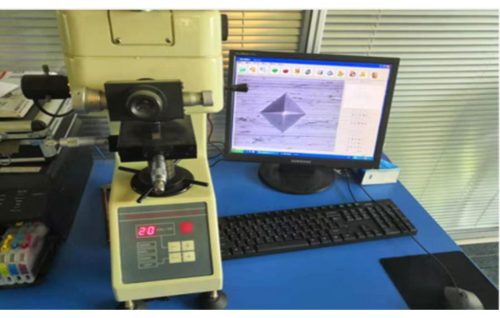

Three major steps to reveal to you why our quality is better

Step 1: Spot check hardness testing for each batch.

We will issue the data with the goods according to your customized requirements; avoid materials that are too soft and unformed, too hard and prone to breakage, headshots, and cracks.

Step 2: Material surface flaw detection

We use turbine flaw detectors to inspect material cracks and defects; material thickness measurement; coating thickness measurement, which can effectively avoid situations such as uneven sizes and material instability.

Step 3: Material Tensile Testing

We use a tensile tester to measure the material’s tensile properties, tensile strength and deformation rate, breaking force, tear resistance and heat sealing strength to avoid substandard toughness.

Contact:

John Wang

Position:

Sales Manager

Mob:

+86-15521124749

Email:

WhatsApp Us Now!